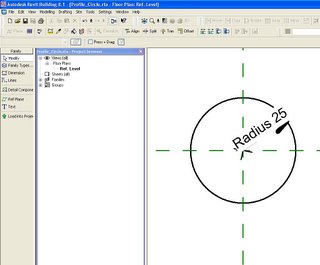

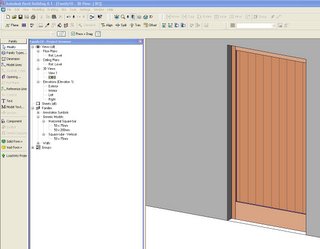

Building families is not always the only manner in which to assemble building components. In some cases one can achieve the same results using the tools provided.

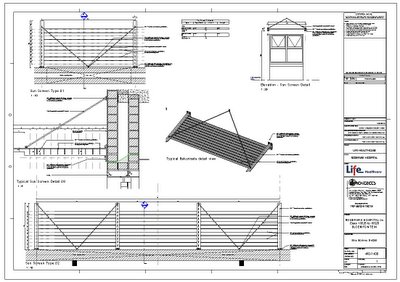

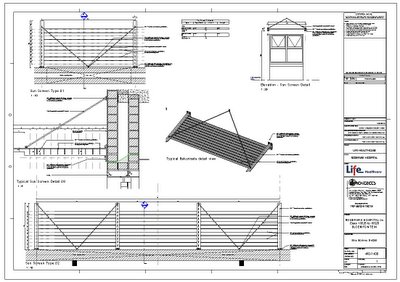

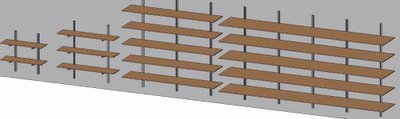

Take the sunscreen for example (image). This could easily have been done using the structural tools, namely, Beams and Beam systems, once grouped, this whole element can then be copied all around the building.

So, I suppose, don’t always jump in head first, sit back and assess which method would be more efficient and less time consuming.

There are all sorts of factors that play a role in making such decisions. For quick design roll-out we just did these as beams and beam systems. For documentation purposes we rebuilt them as families as we needed to schedule the component as a whole.

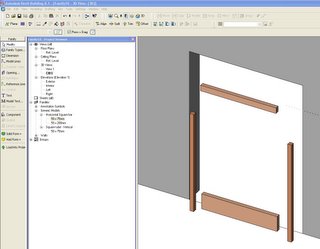

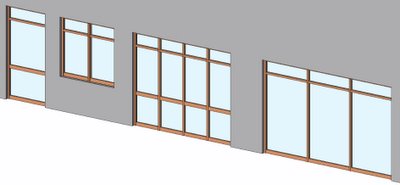

We apply the same methodology to many other components such as windows. For quick designs, we use embedded curtain walls or just generic instance windows, that one can just pull to size. For construction documentation (CDs), we then rebuild them all into window families.

You might ask why do the work twice? Well it all has to do with time constraints in the design process, then scheduling and the ability to place these components as legend components in neat & tidy views in the CDs.

See this post for an example of legend views